pdaXsection

properties.Design layers which map via gridding onto GDS/Oasis/OpenAccess layers. xsection's provide for "optical" logic like default width, bend radius, coupling length and so on.

Each design layer can map to multipe GDS layers, so you can define a layer stack relating to a waveguide in a single definition.

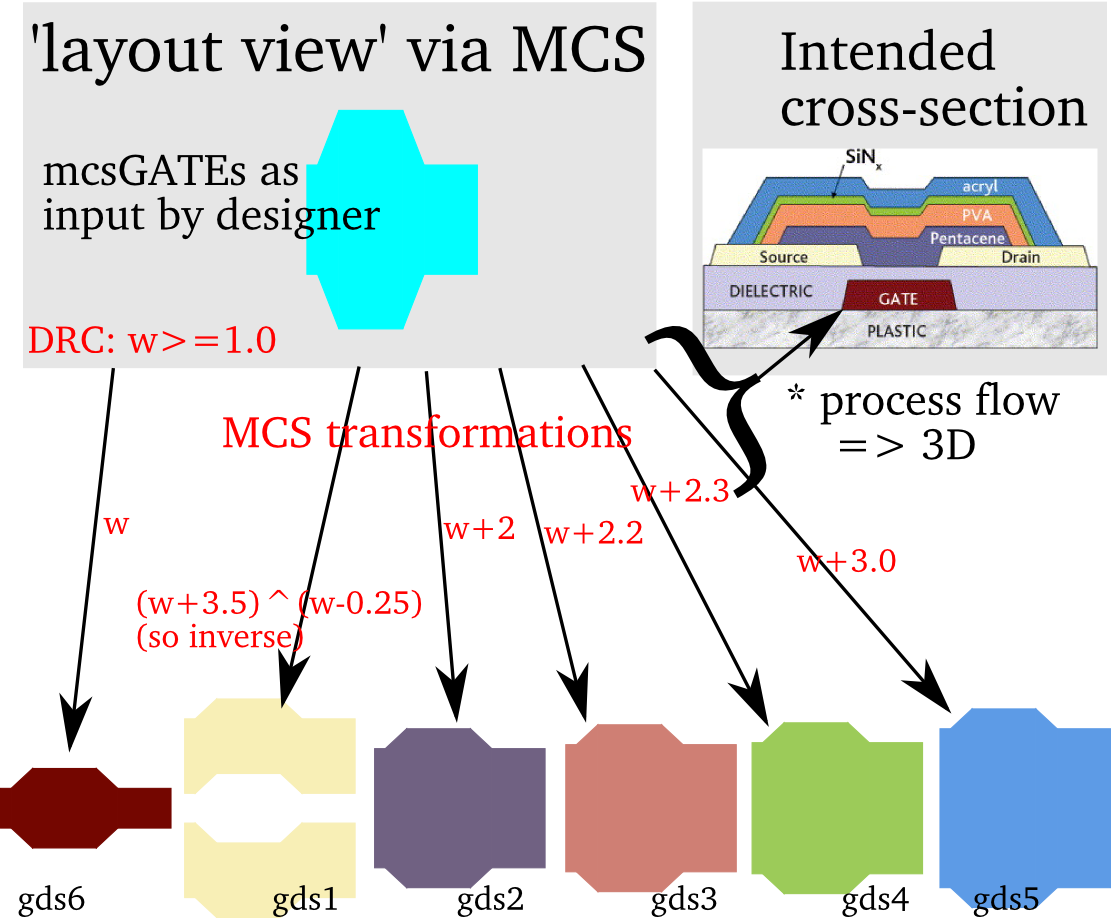

Take for example a typical core, cladding and trench or some under/over etch compensation. This approach is not only suitable for photonics, but is practical in many technologies. The picture below shows a cross-section of a (printed) transistor.

Instead of writing in many GDS layers, you can simply use the

xsection which represents

OptoDesigner's mcs concept which is shown in the picture.xsection

This defines axsection which in EDA-design is often called a cad or design layer.

In OptoDesigner this is a mcs. The xsection's define what the port should refer

to. A xsection is normally something like a waveguide or metal track and is often using

multiple (gds) layers. Very basic definition.

<xsection name="WGbase">

<purpose>Base waveguide</purpose>

</xsection>

Including GDS mapping and some properties

<!-- define GDS layers for the <map> sections -->

<layer name="layer1">

<gds_number>1</gds_number> <gds_datatype>0</gds_datatype>

</layer>

<layer name="layer2">

<gds_number>2</gds_number> <gds_datatype>0</gds_datatype>

</layer>

<!-- define MCS layers -->

<xsection name="WG">

<purpose type="active">Waveguide with grid</purpose>

<grid>

<map accuracy="0.1">layer1</map>

<map widen="2">layer2</map>

</grid>

<xsSetWidth useDrc="false">0.5</xsSetWidth>

<xsSetRadius min="100">200</xsSetRadius>

</xsection>

<xsection name="Doc">

<purpose type="doc">Metal highlighting</purpose>

<grid>

<map accuracy="0.1">layer2</map>

<map widen="2">layer2</map>

</grid>

<xsSetWidth useDrc="false">0.5</xsSetWidth>

<xsSetRadius min="100">200</xsSetRadius>

</xsection>

Structure

The attributes and elements are shown below, in a sorted per type fashion.In case a list is printed after an element, it indicates that you can have many, otherwise it should be a single element. With a optional it tells the element is not required.

<pdaXsection base="..." has_SBoffset_model="..." has_WGmode_model="..." maskNumber="..." mcsAnnotateBoundary="..." mcsAnnotateCellName="..." mcsAnnotateParameter="..." mcsAnnotatePinDC="..." mcsAnnotatePinInfo="..." mcsAnnotatePinOptical="..." mcsAnnotatePinRF="..." mcsAnnotatePinSize="..." mcsAnnotateText="..." mcsAnnotateWaveguide="..." mcsBusConfig="..." mcsMigrate="..." name="..." pdkSelect="..." techLayerID="..." techLayerRouting="..." xsPortMapTo="..." xstype="..." ... > ...

<DesignRule> ... </DesignRule> list

<MRL> ... </MRL> list

<TRL> ... </TRL> list

<WaiveReport> ... </WaiveReport> list

<color> ... </color> list

<doc> ... </doc> list

<fillstyle> ... </fillstyle> list optional

<grid> ... </grid> list

<groupRef> ... </groupRef> list

<linestyle> ... </linestyle> list

<module> ... </module> list

<purpose> ... </purpose> list

<sptFooter> ... </sptFooter> list

<sptHeader> ... </sptHeader> list

<techLayerConnection> ... </techLayerConnection> list

<tex> ... </tex> list

<ticket> ... </ticket> list

<visible> ... </visible> list

<wavelength> ... </wavelength> list

<xsSetGap> ... </xsSetGap> list

<xsSetLength> ... </xsSetLength> list

<xsSetPortCriticalRadius> ... </xsSetPortCriticalRadius> list

<xsSetRadius> ... </xsSetRadius> list

<xsSetSBOffset> ... </xsSetSBOffset> list

<xsSetTaperAngle> ... </xsSetTaperAngle> list

<xsSetTextExpand> ... </xsSetTextExpand> list

<xsSetUncoupledDistance> ... </xsSetUncoupledDistance> list

<xsSetWidth> ... </xsSetWidth> list

</pdaXsection>

XSD The schema file can be downloaded or viewed at xPDK_Base.

Details

DesignRule

Define a 'meta rule', so non-geometric. Type pdaDrcGeneralRule documentation: Define a design rule that is not layer or "polygon" / "geometric" based.Design rules are available in different flavors, some of which can not be associated with layers; for example the name of the GDS cell that is required to be used for the design.

The rule is described in text and software may (or not) be able to implement them. Using the rule field gives designers an easy way to find more information on the DRC fail if it appears.

MRL

Type pdaMRL documentation: Manufacturing Readiness Level (MRL) as defined by the EU.TRL

Type pdaTRL documentation: Technology Readiness Level (TRL) as defined by the EU.WaiveReport

Type WaiveReport documentation: Waive an issue in the Report.htmlbase

color

this is intended to have more consistent look over different software. Type pdaColor documentation: Each of R, G and B is required and be between 0 and 256.doc

Type pdaDocumentation documentation:This field allows some (short, few lines) documentation to be written. It can be a long string, but the idea is not to replace a design manual.

This fields is like

tex

which allows documentation in LaTex format; doc

is restricted to plain text.extend

Type AllowExtend documentation: Allows to extend with any (complex) data for enriching a design kit. The sub-data of an

extend will normally be vendor or provider specific, but may span multiple software

vendors or suppliers.Provider extensions can be references to (or embedded) reporting scripts or their versions; source database references and so on. Such data is helpful in cross-referencing production issues or differences between export snapshots. Embedding such data in the XML rather then side-files enhances tracebility and reduces errors.

Using this section is not considered part of the xPDK format therefore, but as long as the files validate with the Stichting PDAFlow Foundation schema's, it is not considered a (not allowed) Derivative version.

For conventions, please check also Extensions.

See also xPDK License.

fillstyle

(polygon area) default settings in software; this is intended to have more consistent look over different software.Type pdaFillStyle documentation: The options here match typical desktop software / C++ libraries, which makes it very software transferable.

This list is loosely based on the wxWidgets list, see wxPenStyle.

grid

gdslayer is a key aspect. It is handled in thegrid section where

many maps can be defined.Each mapping adds a possibly modified copy using the widening or lengthening of the data to the respective gdslayer.

You can define a mix of

widen, lengthen, accuracy

and so on per map and they will be jointly used for one mapping to the GDS

layer in the <map>...</map>. The name in<map>...</map> should be

the name of a layer or applayer.The examples show only a single attribute per map to keep the example more focussed and the documentation more specific.

An

xsection can have zero grids, this makes it a

display-only layer. To get something into GDS/Oasis/OpenAccess you need to have one or

more gds-layers associated. Each can have a different widening.

Type pdaXsectionGridToLayer documentation:

groupRef

Type pdaIdentifier documentation:Identifiers are used in the Python library for the

getName() and

setName() function and can thus be used to identify the different elements in list

s.In text the specification is a letter, followed by letters, numbers, underscore. The XSD schema validation is a regular expression: [A-Za-z]([A-Za-z0-9_])*

has_SBoffset_model

Type epibool documentation: Wrap a boolean for name space API aspects.has_WGmode_model

Type epibool documentation: Wrap a boolean for name space API aspects.linestyle

contour) default settings in software; this is intended to have more consistent look over different software.Type pdaLineStyle documentation: The options here match typical desktop software / C++ libraries, which makes it very software transferable.

maskNumber

Type maskNumber documentation: Define tech maskNumber.This number somewhat reflects the layerstack and is used in LVS. The lower numbers should be the lower layers in the chip. The range does not need to be continous.

mcsAnnotateBoundary

Type mcsAnnotateBoundary documentation: OptoDesigner extension, use this xsection/mcs for the BB/pcell name in xpdkAnnotator().mcsAnnotateCellName

Type mcsAnnotateCellName documentation: OptoDesigner extension, use this MCS for the BB/pcell name in xpdkAnnotator().mcsAnnotateParameter

Type mcsAnnotateParameter documentation: OptoDesigner extension, use this MCS for BB/pcell parameters in xpdkAnnotator().mcsAnnotatePinDC

Type mcsAnnotatePinDC documentation: Tag DC port in this layer via rectangle.mcsAnnotatePinInfo

Type mcsAnnotatePinInfo documentation: OptoDesigner extension, use this MCS for BB/pcell ports in xpdkAnnotator(). This layer is used for the port name and properties.mcsAnnotatePinOptical

Type mcsAnnotatePinOptical documentation: Tag optical port in this layer via rectangle.mcsAnnotatePinRF

Type mcsAnnotatePinRF documentation: Tag RF port in this layer via rectangle.mcsAnnotatePinSize

Type mcsAnnotatePinSize documentation: OptoDesigner extension, use this MCS for BB/pcell ports in xpdkAnnotator(). This layer is used for a rectangle that indicates the width of the port.mcsAnnotateText

Type mcsAnnotateText documentation: Extension, use this MCS for plain text.mcsAnnotateWaveguide

Type mcsAnnotateWaveguide documentation: This information is intended for Layout-vs-Schematic (LVS) with ICvalidator in OptoCompiler.mcsBusConfig

Type mcsBusConfig documentation: This boolean can be set to true to set up a curve-based bus-config for this xsection in case no BBs are set up for bus-routing for this xsection.Using this value is not needed if there is at least a single BB configured for being a busConfig-element for this xsection; in that case the other non-specified layout's are automatically configured using basic OptoDesigner curves.

mcsMigrate

Type mcsMigrate documentation: and thus to slowly be dropped from the design kit.module

Type pdaIdentifier documentation:Identifiers are used in the Python library for the

getName() and

setName() function and can thus be used to identify the different elements in list

s.In text the specification is a letter, followed by letters, numbers, underscore. The XSD schema validation is a regular expression: [A-Za-z]([A-Za-z0-9_])*

name

Type pdaIdentifier documentation:Identifiers are used in the Python library for the

getName() and

setName() function and can thus be used to identify the different elements in list

s.In text the specification is a letter, followed by letters, numbers, underscore. The XSD schema validation is a regular expression: [A-Za-z]([A-Za-z0-9_])*

pdkSelect

Type pdkSelect documentation: Use in layout.xml's to have a single foundry database, where you select layer/xsection/.. sub-sets for a given PDK. This is typical from a lib directory with a layout_master.xml/h.purpose

this is a short line. Type pdaLayerPurpose documentation: (see oc:techPurpose for values).An optional attribute is type which can have one of the following values: passive, active, doc, misc, metal, metalalt, metalrouting, metal1, metal2, metal3, metal4, metal5, metal6, metal7, metal8, metal9, rf, rf_gsg, rf_gssg, rf_s, rf_g.

Metal1-9 are for multi-layer metal, with '1' being closes to the photonics; moving up to higher numbers is typically done with VIA's.

sptFooter

Type sptFooter documentation: This section will be put at the end of a definition via XSLT.Tech/02 definition

This section is copied into the '02' file just before the function export()The typical use is for backward compatability (for example mapping older mcs names) or some custom tech functions that need access to most of the tech-file.

Using this element instead of the TechFooter is easier in case of enriching the design kit via the C++ or Python library.

pdaSingleLayerOPS

This section is copied into the '02' file below the (gds/mcs) layer definitions in the single-layer operation block. It is intended for more complex single/multi layer derived operations or DRC.Download the xsl/xml/xsd's and run the (bash) command line below to convert the XML to a SPT example in OptoDesigner (see short docu):

xsltproc --xinclude -stringparam standalone true -stringparam example drc0 xPDK_toOptoDesigner02.xsl layer_singleSpt.xmlfull file

<visible>true</visible>

<fillstyle>NOFILL</fillstyle>

<linestyle>DRAW</linestyle>

</layer>

<layer name="layer2">

<gds_number>2</gds_number>

<gds_datatype>0</gds_datatype>

<grid>0.001</grid>

<purpose>Waveguide layer</purpose>

<color R="255" G="20" B="20"/>

<visible>true</visible>

<fillstyle>NOFILL</fillstyle>

<linestyle>DRAW</linestyle>

Spt:

xsection

This section is copied into the '02' file below the mcs definition and is intended for more complex properties like waveguide models and so on.It provides also for less common mcsSet*() functions or feeding them with values that xPDK does not support.

</doc>

<xsection name="WG">

<od:sptHeader>// This section does some special OptoDesigner things.

mcsSetCurveCheck();

mcsSetAltWG("WGhigh","WGlow");

</od:sptHeader>

</xsection>

BB definition

This section is copied into the '04' file inside the layout definition and is intended for fine-tuning behavior, giving control over returned attributes and so on. In typical cases it is not needed.Use this field in case the xPDK format does not have all the fields you need for your BB in OptoDesigner. For example this is possible for returning more layout attributes or supporting more complex design rule checking.

<bb name="myBB">

<port label="in0">

<position>

<x>0</x>

</position>

</port>

<od:sptFooter>

ml::Straight(cin-> this@in0:wfix(1),20) elm;

this{"elm"}=elm;

this{"L"}=20;

</od:sptFooter>

</bb>

BB boundary

This section is copied into the '04' file into the layout itself and can be used to mark up complex boundaries. Also the use of multiple mcs/gds layers for DRC can be simpler this way.Instead of using spt, you can also use the xsection for typical cases and reduce vendor dependence for this section.

</doc>

<bb name="myBB">

<port label="in0">

<position>

<x>0</x>

</position>

</port>

<boundary>

<od:sptHeader>

ml::Straight(cin-> this@in0 : wopar(1,3),20);

</od:sptHeader>

</boundary>

</bb>

sptHeader

Type sptHeader documentation: This section will be put at the start of a definition via XSLT.Tech/02 definition

This section is copied into the '02' file at the start of the TechnologyPDKLIB class instance.The typical use is waveguide mode models and other bigger spt sections that can then be used in the different sections.

pdaSingleLayerOPS

This section is copied into the '02' file below the (gds/mcs) layer definitions in the single-layer operation block. It is intended for more complex single/multi layer derived operations or DRC.Download the xsl/xml/xsd's and run the (bash) command line below to convert the XML to a SPT example in OptoDesigner (see short docu):

xsltproc --xinclude -stringparam standalone true -stringparam example drc0 xPDK_toOptoDesigner02.xsl layer_singleSpt.xmlfull file

<visible>true</visible>

<fillstyle>NOFILL</fillstyle>

<linestyle>DRAW</linestyle>

</layer>

<layer name="layer2">

<gds_number>2</gds_number>

<gds_datatype>0</gds_datatype>

<grid>0.001</grid>

<purpose>Waveguide layer</purpose>

<color R="255" G="20" B="20"/>

<visible>true</visible>

<fillstyle>NOFILL</fillstyle>

<linestyle>DRAW</linestyle>

Spt:

xsection

This section is copied into the '02' file below the mcs definition and is intended for more complex properties like waveguide models and so on.It provides also for less common mcsSet*() functions or feeding them with values that xPDK does not support.

</doc>

<xsection name="WG">

<od:sptHeader>// This section does some special OptoDesigner things.

mcsSetCurveCheck();

mcsSetAltWG("WGhigh","WGlow");

</od:sptHeader>

</xsection>

BB definition

This section is copied into the '04' file inside the layout definition and is intended for fine-tuning behavior, giving control over returned attributes and so on. In typical cases it is not needed.Use this field in case the xPDK format does not have all the fields you need for your BB in OptoDesigner. For example this is possible for returning more layout attributes or supporting more complex design rule checking.

<bb name="myBB">

<port label="in0">

<position>

<x>0</x>

</position>

</port>

<od:sptFooter>

ml::Straight(cin-> this@in0:wfix(1),20) elm;

this{"elm"}=elm;

this{"L"}=20;

</od:sptFooter>

</bb>

BB boundary

This section is copied into the '04' file into the layout itself and can be used to mark up complex boundaries. Also the use of multiple mcs/gds layers for DRC can be simpler this way.Instead of using spt, you can also use the xsection for typical cases and reduce vendor dependence for this section.

</doc>

<bb name="myBB">

<port label="in0">

<position>

<x>0</x>

</position>

</port>

<boundary>

<od:sptHeader>

ml::Straight(cin-> this@in0 : wopar(1,3),20);

</od:sptHeader>

</boundary>

</bb>

techLayerConnection

Type techLayerConnection documentation: Define OA-Tech layer connection.This field can be used to link layers and/or xsections; this tells that routing-wise ('design intent') they are directly connecting, possibly with a byLayer value.

You can define the connection in either layer/xsection, no need to define it twice.

For layer/xsection's that connect to more than one, define them from one layer, otherwise multiple lines will be written in the tech file.

Only use this for layers that have at least one of techLayerRouting='true' or techIncludeElectricalTag='true'.

techLayerID

Type techLayerID documentation: Define OA-Tech ID.The OA Tech file needs to have unique numbers that are PDK version constant for design migration. The default behavior is to use for layer definitions 65536*gds_number+gds_datatype and for the xsection the value 10000+N with N being the index in the xsection list.

Those values are very likely to be unique per PDK, but the xsection numbers are unlikely to be PDK version constant (adding or removing xsection's will fail this).

You can overrule the Tech ID with this field; the range is 256-10000 to avoid overlapping the default range. The number is free within this range, but as guideline:

- 1000 - 1999 use this range for optical layers

- 2000 - 2999 use this range for electrical layers

- 3000 - 3999 use this range for mask annotations

- 4000 - 4999 use this range for LVS recognition

techLayerRouting

Type techLayerRouting documentation: Mark for routing in in OptoCompiler tech file, section 'constraintGroups'tex

Type pdaTexDocumentation documentation:doc

, but tex can be a long text in LaTex format to

document the layer in more detail if needed.You can document anything relevant for the topic you want to define.

Multiple paragraphs is fine. Format is Latex, so more complex content is possible.

ticket

Type pdaTicket documentation:visible

intended to have more consistent look over different software.wavelength

Type wavelength documentation: For the xsSet--() functions the wavelength is important; the xPDK standard assumes single-band definitions for now, but multi-band / wavelength support is needed. This field is therefore likely to move towards the standard.The options in this field are used for wavelength / band selection in the technology. The field itself is a string, so you can use things like "C" or "O-band" as well as values like "0.2 um" or "1550 nm".

xsPortMapTo

Type xsPortMapTo documentation: Define the xsection to use for port properties in case it should not be itself. This is intended to simplify port-xsection consistency tests. See OD.02 mcsAdjust() as reference.xsSetGap

uncoupled. It relates to xsSetUncoupledDistance, but this is suitable for tapering elements also.

<xsection name="WG">

<xsSetGap>2.0</xsSetGap>

</xsection>

xsSetLength

Using this value in the BB-sections of xPDK simplifies maintenance. It also shows better the intent of certain equations / values. Type pdaXsectionItem documentation: for the minimum also. This can be used in BB design or parameter.If min is set, then OptoDesigner will also validate curves against this value - so the "logical" value rather (per-se) the geometrical value as due to grid/map you may have different values for that.

If this is not intended, use useDrc="false" as attribute.

xsSetPortCriticalRadius

"straight".Using this is typically for a low contast waveguides which need SBoffsets. Radii above this value are ignored in connectivity tests to avoid radius conflicts where unneeded. With radius below this value, the design software can give warnings on mismatch in radius, which indicates you need transition elements (in schematic design) or (in layout-only design) a geometrical offset to ensure low transistion losses in the guided modes.

You can use a negative value to disable those tests. The test should only be done in case the port-radius is set, so not using them will also block such connections warnings. Type pdaExpressionXt documentation:

xsSetRadius

curved / bended waveguides.The waveguide/port bend radius is measured with respect to the geometrical waveguide center (in the case of most common symmetric waveguides).

Using this value in the BB-sections of xPDK simplifies maintenance. It also shows better the intent of certain equations / values.

<xsection name="WG">

<xsSetRadius useDrc="false" min="1">50.0</xsSetRadius>

</xsection>

If min is set, then OptoDesigner will also validate curves against this value - so the "logical" value rather (per-se) the geometrical value as due to grid/map you may have different values for that.

If this is not intended, use useDrc="false" as attribute.

xsSetSBOffset

transistion for the default width/radius.You can use the <spt> to define more complex (radius dependent) values also or apply a complete mcsModeModel for that.

These are OptoDesigner specific values, but the typical width/radius is often used.

<xsection name="WG">

<xsSetSBOffset>0.01</xsSetSBOffset>

</xsection>

xsSetTaperAngle

for automatic tapers when width-changes are detected.Recommended is to use an angle that is low enough to avoid mode or polarisation conversion.

<xsection name="WGbase">

<xsSetTaperAngle>1.0</xsSetTaperAngle>

</xsection>

xsSetTextExpand

grow the pixels of a text font.This is often needed to prevent design rule fails on small vertices or sharp angles.

<xsection name="WG">

<xsSetTextExpand>20</xsSetTextExpand>

</xsection>

xsSetUncoupledDistance

curves for which they are to be reasonably uncoupled.The reasonable is not a hard specification, but indicative. Reasonable values are when the coupling length will be close to the chip length.

<xsection name="WG">

<xsSetUncoupledDistance>2.0</xsSetUncoupledDistance>

</xsection>

xsSetWidth

Using this value in the BB-sections of xPDK simplifies maintenance. It also shows better the intent of certain equations / values.

<xsection name="WG">

<xsSetWidth useDrc="false" min="0.1">0.5</xsSetWidth>

</xsection>

If min is set, then OptoDesigner will also validate curves against this value - so the "logical" value rather (per-se) the geometrical value as due to grid/map you may have different values for that.

If this is not intended, use useDrc="false" as attribute.